MORESUPERHARD

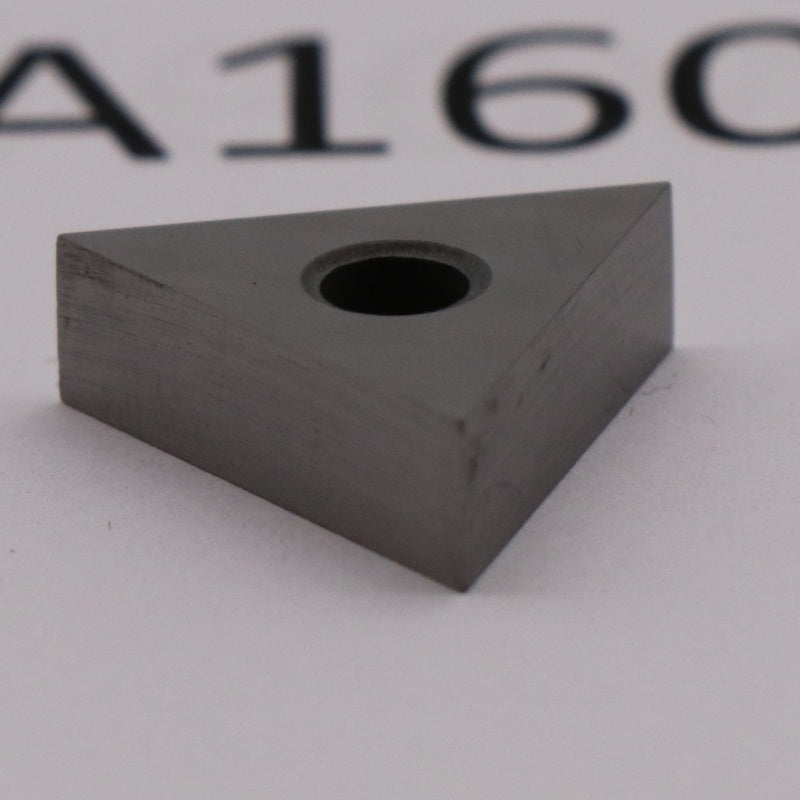

10pcs/box TNGA 1204 Carbide Inserts Metal Lathe Machining

10pcs/box TNGA 1204 Carbide Inserts Metal Lathe Machining

Couldn't load pickup availability

Note - Always check item size carefuly before pucharsing

- Carbide Inserts are made of high quality carbide material, not easy to rust and durable.

- Carbide Inserts are hard and sharp, cutting faster and more efficient.

- Package : 10pcs/box

Moresuperhard TNGA Carbide Inserts are designed for metals with low to medium-high hardness, and some non-metallic materials. Perfect for Low-medium hardness steel (HB150-250, HRC15-25), medium-high hardness steel (HB250-450, HRC25-38), low-medium hardness cast iron (HB180-255, HRC17-25), medium-high hardness cast iron (HB255-350, HRC25-32), non-ferrous metals including aluminum and aluminum alloys (HB50-120, no HRC value) and copper and copper alloys (HB80-180, no HRC value), engineering plastics (Rockwell hardness R80-110), and soft wood and wood-plastic materials. Carbide inserts deliver exceptional performance on both manual and CNC machines.

Applications of Carbide Inserts

Usage: Turning, milling, drilling, boring, cutting off / grooving

- Low-carbon steel, medium-carbon steel, ordinary alloy steel

- Quenched and tempered steel, stainless steel, annealed bearing steel

- Gray cast iron, nodular cast iron, malleable cast iron

- High-silicon cast iron (Si15), nodular cast iron (QT600-3)

- 6061 aluminum alloy, 7075 aluminum alloy, ADC12 aluminum alloy

- H62 brass (pipe fittings), QSn6.5-0.1 tin bronze (bearing bushes)

- Nylon 66 (gears), POM (bearings), PVC (pipes)

- Rigid wood-plastic boards (furniture panels), medium-density fiberboard (MDF)

Advantages of Carbide Inserts

- Strong wear resistance: Service life far exceeds traditional cutting tools, reducing tool change frequency

- High hardness with moderate toughness: Suitable for low-medium hardness materials, less prone to chipping

- High cutting efficiency: Fast machining speed, shortening the processing time per piece

- Wide versatility: Covers multiple materials and processing methods, reducing tool inventory

- High cost-effectiveness: Moderate unit price, low overall cost

- Good thermal stability: Stable performance at high temperatures, preventing "tool burning"

Why Choose Moresuperhard Carbide Inserts?

- Premium Raw Materials – Ensuring wear resistance and long service life.

- Advanced Manufacturing Techniques – Precision grinding and strict quality control.

- Competitive Pricing – Same quality level as world-renowned brands at a lower cost.

- Industry Expertise – Based in Zhengzhou, benefiting from China’s industrial concentration advantages.

Shipping & Handling

Shipping & Handling

We support global shipping. After your purchase, we will ship within 24 hours and the shipping method will be FedEx or DHL air freight, with fast shipping time.

Environment-Friendly

Environment-Friendly

Our grinding wheels are very environmentally friendly from production to shipment. On the premise of ensuring the rigidity and hardness of the grinding wheel, we have carried out weight reduction treatment on the grinding wheel, which can not only reduce carbon dioxide emissions during transportation, but also save the usage load of your machine and improve its service life.

After-sales Guarantee

After-sales Guarantee

We are the source manufacturer of grinding wheels, after the purchase of the goods have any questions or quality problems can contact us at any time to provide 30 days unconditional refund

Note

Note

To avoid situations where it cannot be used normally, please confirm the size again before placing an order to ensure it is suitable. You can consult us anytime for any questions.

Share